PRINT PRODUCTION

Production Manager

|

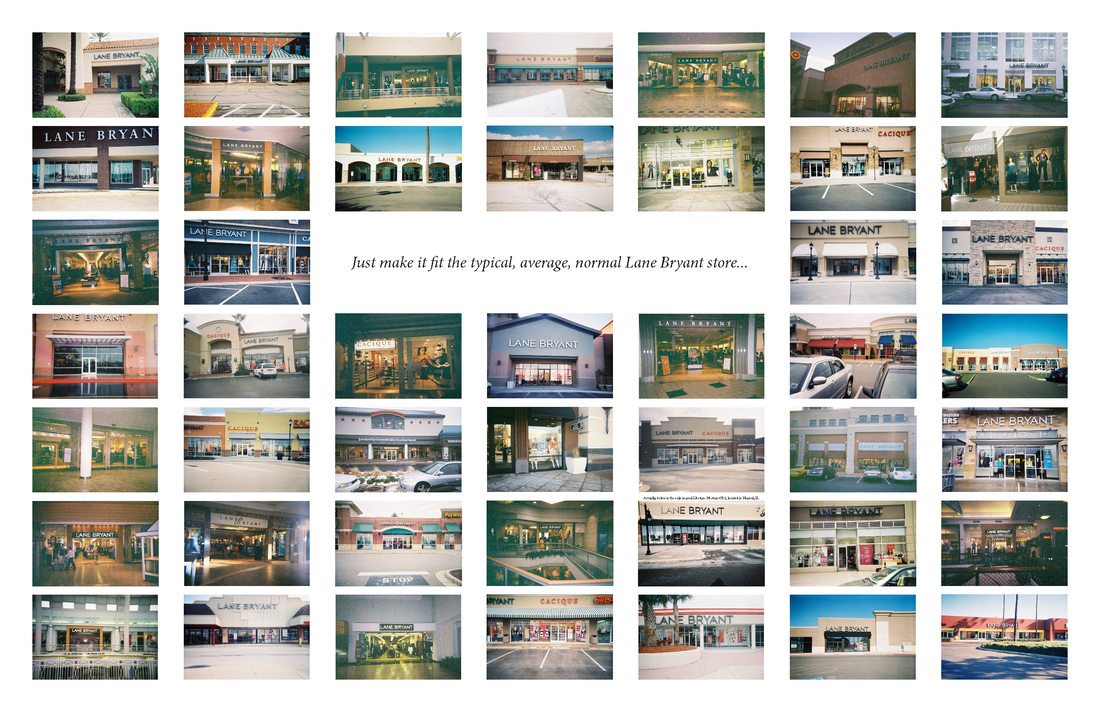

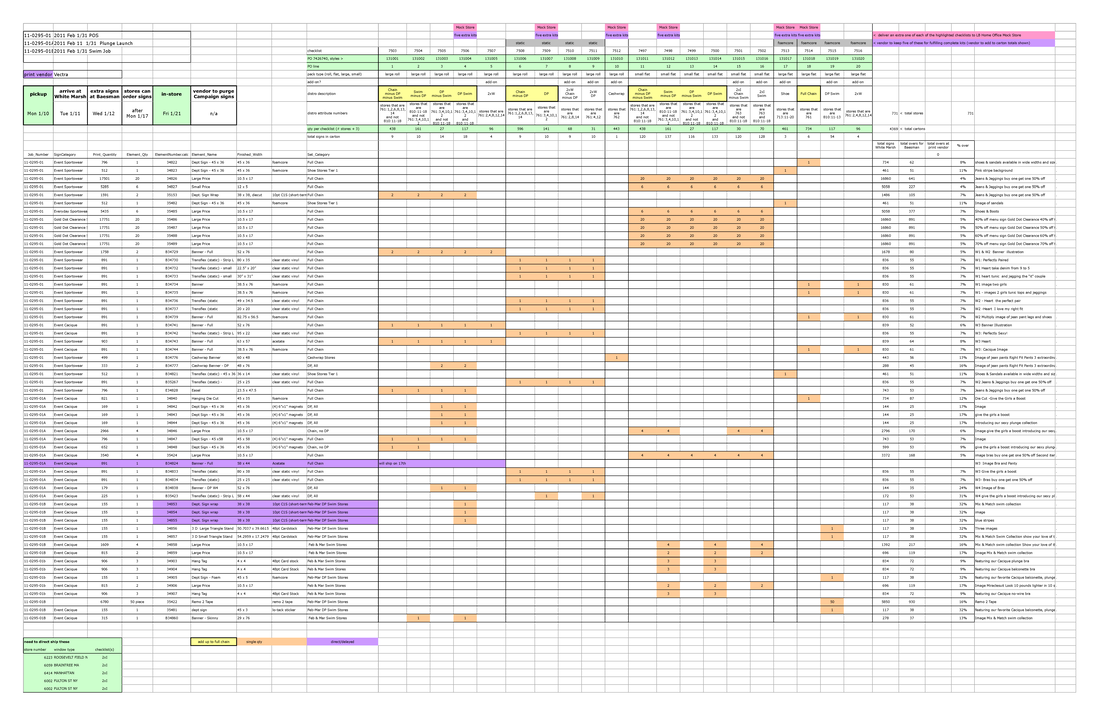

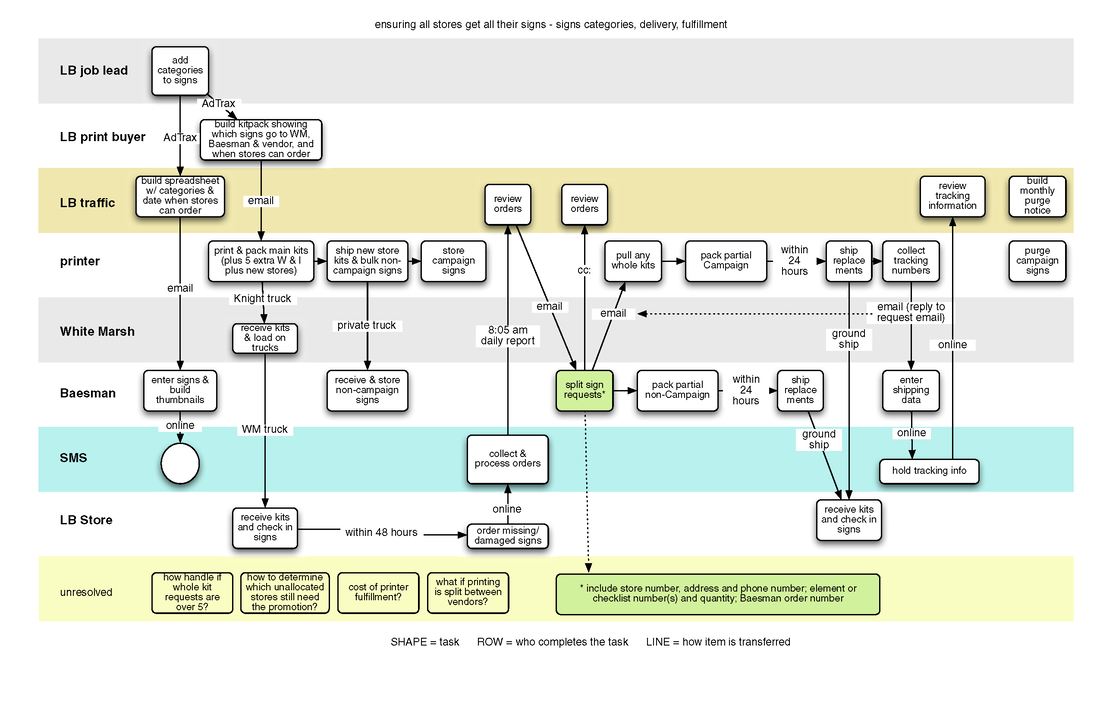

For years I handled "every sign, every store" for four national retail brands. I was responsible for prototyping, buying, tracking, and managing the printing and on-time/on-budget delivery of about 3,000 custom signs a year (totaling 8,000,000 pieces packed in 50,000 boxes). I handled all vendor communications, daily interactions with internal Marketing, Operations, and Finance teams, POs, and monthly invoice reconciliation. I documented saving the company many millions of dollars by finding significant cost reductions every year. These included rebate programs, efficient printing and packing techniques, a $300,000 UPS fee error, and $2.1 million by changing a sign construction method. The change eliminated oversized shipping charges without reducing the sign's visible marketing surface area. Ops, Finance, and Marketing were all happy.

|

Production art

|

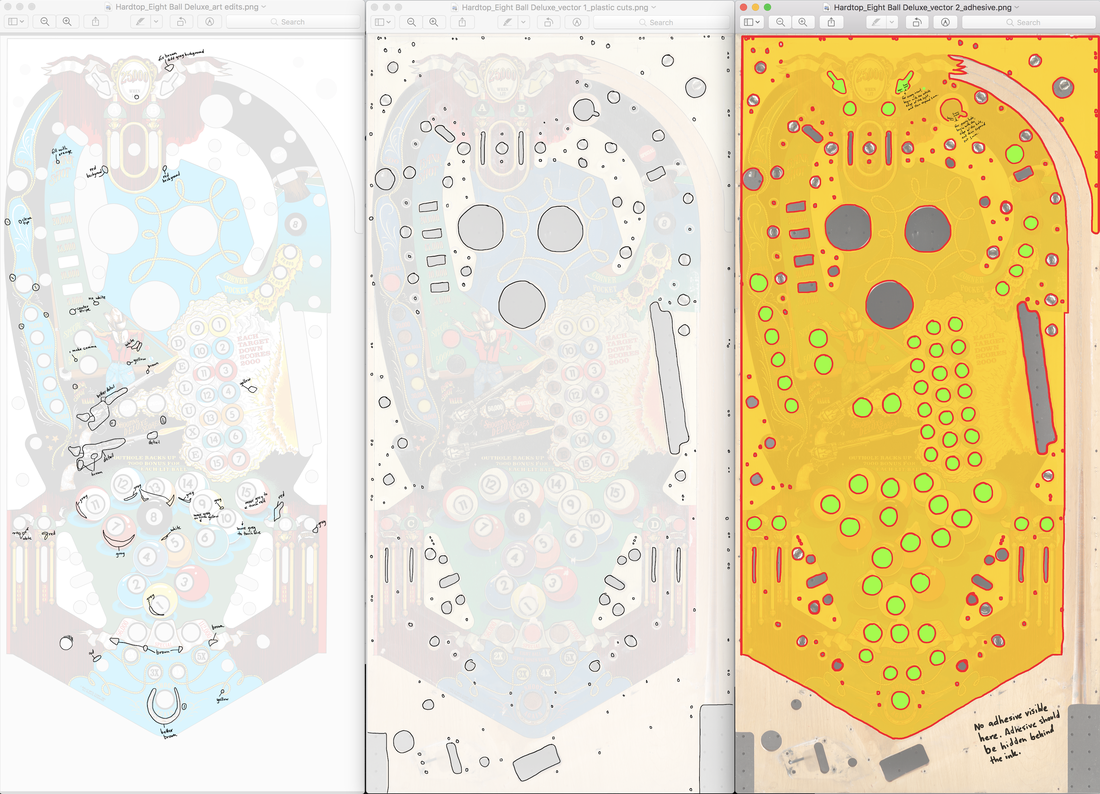

Great ideas need great execution. I've been trusted to build production art, direct retouching, handle quality control, test new materials, and ensure the final product looked as intended for national retail chains, global ad agencies, major automotive companies, and even little pinball product companies.

Sometimes it's making sure the bleed, trim, and live areas are set up correctly for a magazine ad. Sometimes it's press checking an 800,000 piece catalog run in the middle of the night to ensure excellent color matching. Or, marking up art corrections for a 9-color pinball playfield with installation holes. Creating pixel-perfect files for a website header. Testing a color scheme for contrast for colorblind users. Choosing a material based on cost, longevity, availability, and how well it will print, fold, tape, glue, hang, or stand up. There's just a certain satisfaction when a final piece shows up, and the Creative Director gives you a smile and shows it around the department because you nailed it. |

Packaging ProductionSpot color with metallic on 24pt board. Plastic zip-open packs. Wrap-around paper labels. Metal cans. 4/C images on waxed paperboard. Paper labels stuck to round cheese balls. Flexography, screen printing, web, offset, digital. I've helped put a lot of different inks on a lot of different materials.

One company actually offered me a full-time job after I handled a press check for them. I pulled a shopping bag job off the press because I noticed the paper they had selected was not opaque when the bag was standing upright. The medium blue pattern inside was clearly visible through the orange color outside. It required a quick redesign, but my action saved the huge cost of reprinting the whole run. |

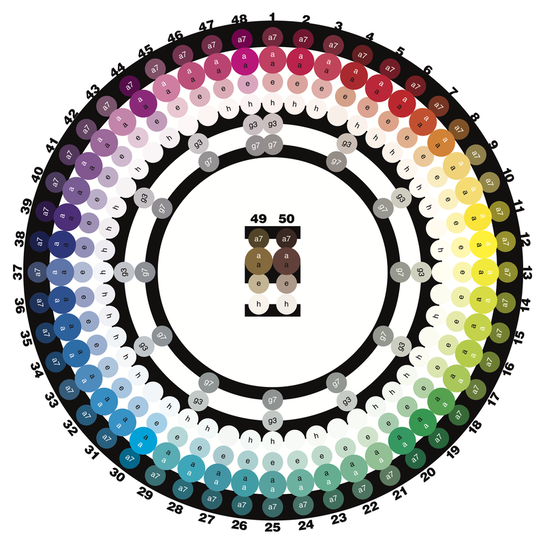

Trumatch color wheelI like the Trumatch system as a Pantone-alternative when choosing spot colors for 4/C process. The system is logical and easy to use. It’s 48 numbered hues arranged in a color wheel, with tints/saturation in evenly-stepped visual increments (from a-h), and shades in darkening steps of adding 6% black (from 0-7, so 0%, 6%, 12%, 18%, up to 42%). It's easy to pick colors "in-between" other colors by doing a little simple math.

I built this color wheel to have the Trumatch color range on one page. I use it as a tool to select accurate colors for specific digital printers, especially in-house laserprinters. I place my EPS file into the same application I'm using for my output, and print. Then I use the print as my swatchbook. I find the color I want, enter the CMYK values (no matter how it looks on the screen), and voila, my output matches. It's great for representing brand colors the first time without having to keep adjusting back and forth. I would even send the file to my digital vendors so we had a color reference for their printers. I found it really useful over the years. Please feel free to pass it along! The PDF file has the instructions. The EPS file is great if you already know what to do. |

| ||||

Window cling reflection simulatorWindow cling designs were often presented as perfect laserprints on paper. This didn't factor in glass reflections caused by bright exteriors and darker interiors. I built a layered file that allowed quick simulation of the reality of window reflections. It facilitated easy evaluation of legibility without having to send out for a sample print and install it on an actual exterior window.

|

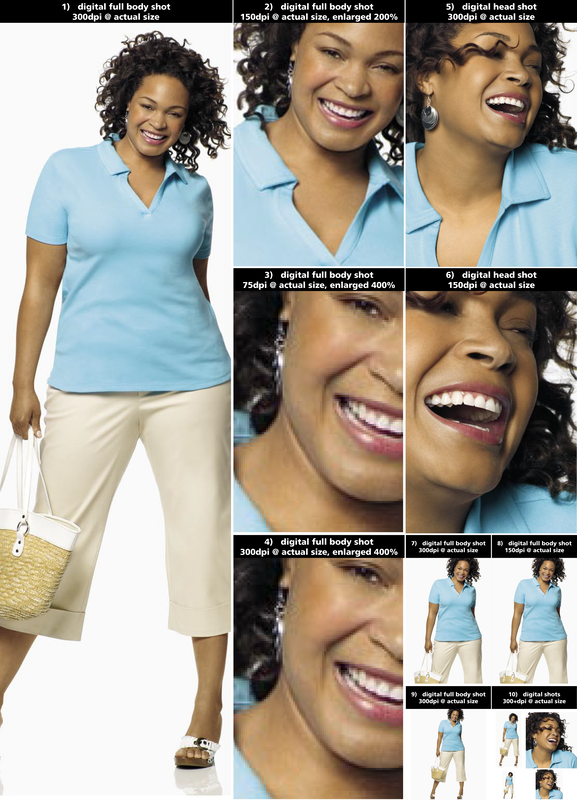

Digital photography enlargement testWe were switching to digital photography for all photoshoots. Instead of using the suggestion to print a single image banner, I created a test banner comparing different enlargements of a head shot and a full body shot. I then had the sheet screenprinted. This was our typical banner production method, as digital was still cost-prohibitive at our high volume.

The end result was a single test sheet that instantly convinced the design team of three things:

|